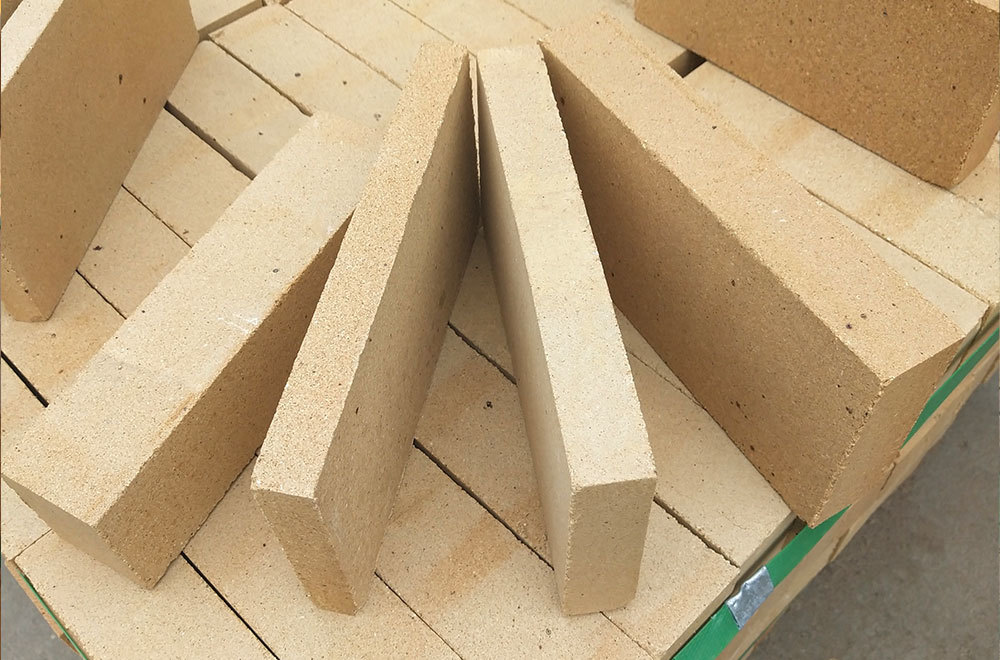

lightweight refractory bricks

Product Description

Product Specifications: 230*114*65mm

Low thermal conductivity, good thermal insulation effect, low heat melt, little heat energy storage, obvious energy saving effect in intermittent operation.

Clay lightweight thermal insulation brick is also called lightweight clay brick. Its thermal properties include its heat capacity, thermal expansion and temperature conductivity. These properties are the basis for measuring whether lightweight clay bricks can adapt to the heat process. According to these indicators, the structure of the equipment is designed to produce clay thermal insulation bricks with performance.

Heat capacity refers to the heat absorbed by the temperature of the material rising by 1000C. The heat capacity of lightweight clay bricks directly affects the heating and cooling speed of the masonry kiln; the thermal expansion of clay bricks is the property of the material increasing in volume with the increase of temperature., it is not a constant value and changes with temperature. The thermal expansion performance is closely related to the structure and strength of lightweight clay bricks. Clay bricks with high strength have a lower thermal expansion coefficient; temperature conductivity is the material. During the heating or cooling process, the speed at which the temperature is transferred to the surrounding space, the higher the thermal conductivity of lightweight clay bricks, the faster the temperature propagation speed, and the temperature difference between places The smaller.

Lightweight viscous brick thermal insulation refractories refer to refractories with high porosity, low bulk density and low thermal conductivity. Thermal insulation refractories are also called lightweight refractories, which include thermal insulation refractories, refractory fibers and refractory fiber products.

Lightweight clay bricks have a wide range of applications, mainly used in thermal equipment and the thermal insulation layer of industrial kilns. They can be used for parts without strong high temperature molten materials to erode and initialize. Some surfaces in direct contact with the flame are coated with a layer of refractory coating to reduce slag erosion and furnace gas soot initialization, reducing damage. The working temperature of the product does not exceed the experimental temperature of the change of the reburning line.

Our Strength

Related products

Leave A Message

Contact: Mr. Sun

Tel: +86-533-7053358

Phone: +86-19905337853

WhtasApp: 86-19905337853

E-mail: Jgang@jingangrefeactory.com

Address: Middle section of Baoshan Road, Wangcun Town, Zhoucun District, Zibo, Shandong, China

WhtasApp: 86-19905337853

Copyright © 2023 Shandong jingang Refractory Co., Ltd.